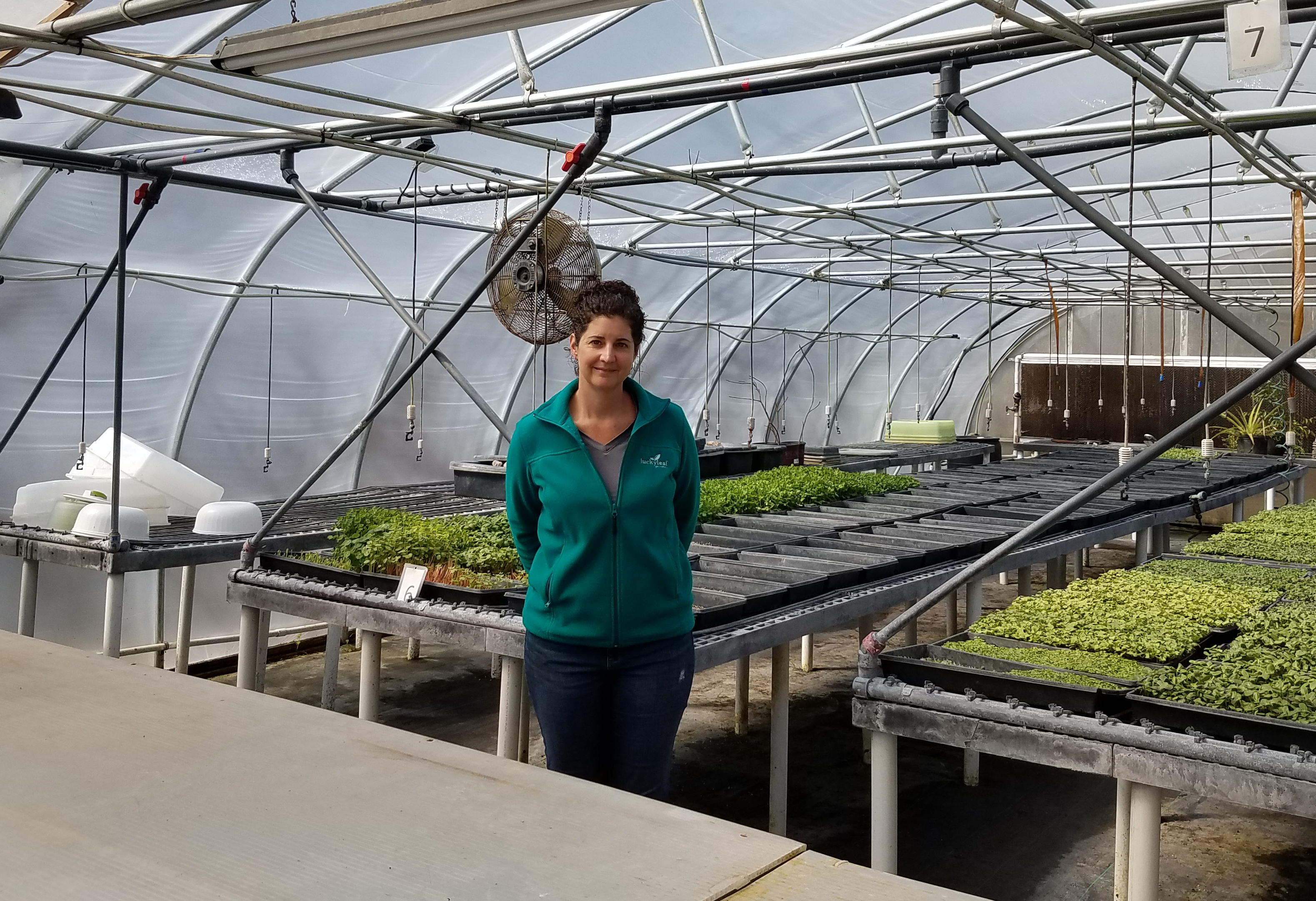

Lucky Leaf Gardens, LLC (“LLG”) (www.luckyleafgardens.com), headquartered in Harrisburg, North Carolina, has been owned and operated by Kate Brun since the company’s 2010 launch. Initially located at her home, the greenhouse-based farming operations are now located at the Forest Farm, a five-acre offsite farm in rural Concord, North Carolina, which includes an “edible forest” of fruit trees and plantings, and a large open-air pavilion featuring a stone wood-fired hearth for events and cooking classes. From its state-of-the-art 3,600 square foot greenhouse, LLG produces fifty varieties of grown-to-order microgreens, which it distributes via regional grocery stores (including Harris-Teeter, Whole Foods, and Earth Fare) and wholesale distributors (including Sysco, USFoods, FreshPoint, and Foster Caviness), and directly to regional restaurants and chefs.

Tape Log

| Time | Subject |

| 0:00:07 | Introduction |

| 0:00:48 | Kate Brun (“Kate”) introduces herself, her background, and the start of Lucky Leaf Gardens (“LLG”) out of the solarium at her home |

| 0:01:56 | Kate describes her education background and past work experience |

| 0:02:42 | Kate’s lifelong interest in gardening and LLG’s first sales of microgreens produce in May 2010 |

| 0:03:12 | Transitioning a gardening hobby into a business |

| 0:03:47 | The early days of LLG |

| 0:04:27 | Kate explains microgreens, their growth cycles, shelf life, and nutritional benefits |

| 0:06:14 | The differences between microgreens and sprouts, including the potential health risks associated with consuming sprouts |

| 0:07:17 | LLG’s evolution and business expansion from a home business into a greenhouse operation; the transition from a home farm to LLG’s Forest Farm |

| 0:09:07 | The learning curve and trial-and-error education in microgreen cultivation, including the constant improvements of processes and equipment |

| 0:10:47 | The evolution of LLG’s customized soil heating system as an example of those constant learnings and iterations of farming and business operations |

| 0:12:37 | The development of LLG’s harvesting practices and distribution network |

| 0:14:57 | The impact of weather and growing seasons on greenhouse agriculture |

| 0:16:17 | The adoption and use of technology in LLG’s farming operations, including technologies enabling constant monitoring of Forest Farm as a remote farm location |

| 0:18:12 | The functionality and durability of LLG’s greenhouse structure |

| 0:19:02 | Climate control of the soil and air in the greenhouse |

| 0:19:33 | The selection of crop varieties to accommodate customer needs and expectations |

| 0:20:52 | LLG’s more successful crop offerings |

| 0:21:57 | The evolution of LLG’s distribution network, from farmers markets to restaurants and grocery stores to local and national retailers and wholesalers |

| 0:24:47 | The challenges of regional direct-to-consumer produce shipments |

| 0:26:07 | The benefits of shipping harvested microgreens versus still-growing microgreens |

| 0:26:52 | Typical daily and weekly schedule for LLG |

| 0:27:27 | LLG’s minimal work force: Kate, her father, and occasional short-term help |

| 0:29:07 | LLG’s less-successful crop offerings, including edible flowers; how the greenhouse’s specific design for microgreens impacts its utility for growing other crops |

| 0:30:07 | Watering and shade cloth practices for greenhouse farming |

| 0:31:07 | LLG’s compost practices as an example of the trial-and-error evolution of farming practices |

| 0:33:02 | LLG’s organic farming practices |

| 0:33:47 | The ongoing debate whether to pursue organic certification, and its questionable value given LLG’s condensed growing season and current organic farming practices |

| 0:34:37 | Food safety, USDA audits and inspections, and LLG’s voluntary USDA “Good Agricultural Practices” (GAP) certification |

| 0:35:43 | LLG’s Food Safety Management Act readiness, despite its exempt status under the Act |

| 0:36:47 | LLG’s Forest Farm and ongoing efforts to use the property to grow community and farming awareness |

| 0:37:27 | LLG’s use of Permaculture Techniques in managing Forest Farm; the edible forest |

| 0:38:31 | Forest Farm’s outdoor pavilion and wood-fired oven for community pizza nights |

| 0:39:27 | Outdoor classes taught at the pavilion, including bread-making, kraut, mushrooms, sourdough, and planting for human health |

| 0:40:12 | LLG’s experimentation with hops cultivation |

| 0:41:55 | Fruits cultivated in the Forest Farm’s edible forest |

| 0:42:57 | LLG’s educational mission, including with local schools |

| 0:45:12 | Challenges and public misperceptions of greenhouse farming and microgreen agriculture |

| 0:46:14 | Kate’s course of self-education about microgreens and greenhouse operations |

| 0:47:22 | The Charlotte microgreen industry and market |

| 0:49:17 | LLG’s involvement with Piedmont Culinary Guild; Kate’s view of Charlotte’s potential future as a “foodie” town and culinary destination |

| 0:52:07 | Microgreens versus staple/commodity crops; greenhouse farming versus traditional outdoor agriculture, and the different challenges facing each type of farming |

| 0:54:54 | Public misperceptions about agriculture in general |

| 0:55:47 | Future plans for LLG and the Forest Farm |

| 0:56:52 | Kate’s view of Charlotte’s agricultural future, and the growing age shift of farmers |

| 0:58:57 | The return to heirloom crops |

| 0:59:57 | Changing consumer awareness of food and dietary issues and the impact on farmers and farming |

| 1:02:27 | Kate’s advice for consumers wanting to learn more about food and dietary issues |

| 1:03:03 | End of interview |

Transcript

[00:00:07]

>> Okay, so this is Tommy Worlick, today is Thursday, April 4th, 2019. I am working with the UNC Charlotte History Department on the oral history project, the Queen’s Garden, oral histories of the Piedmont food shed. And today I am at the forest farm of lucky leaf gardens with Kate Brunn who is the founder owner and operator.

[00:00:33]

Kate, good morning.

>> Morning.

>> Greatly appreciate you spending time with us and letting us speak with you today about the gardens and about your business. Can I get you to start by just sort of telling us about yourself, your background and how Lucky Leaf Gardens came in to being.

[00:00:49]

>> Yeah, so I’m Kate, we moved to Charlotte 14 years ago now, and at that time we were kind of in transition with our careers. Long story short, I had a sun room on the back, and still have the sun room on the back of my house. It’s a glass roofed solarium, octagon shape, probably why I bought the house and probably why my husband hates the house.

[00:01:19]

[LAUGH] It was leaking, it’s cold, it’s hot, you can’t really use it. Mark, my husband was threatening to tear it off and put something better. And I said well what if we turn it into a little greenhouse and maybe we can grow some winter greens, or something. And within a month, we had a operation of microgreens, because that’s about the only thing you can grow in such a small space.

[00:01:44]

And we were selling, we had our business up and running within a month, website, business cards, door to door, selling microgreens.

>> My gosh. Now, you were telling me, your educational background at Radford University-

>> Radford University in Radford, Virginia.

>> But what did you do before you were a real estate agent?

[00:02:01]

>> I worked as a contractor for the EPA in region eight, Colorado, and we were mapping contaminated soils through GIS which was back then, somewhat of a new technology. Now it’s very, I mean, everybody’s using it on their phone every day.

>> And your studies at Ratford were in environmental science?

[00:02:23]

>> Environmental, well, it’s in the geography department, it was three or four tiers down, but ultimately, a geography degree in environmental studies, concentration in GIS with a minor in geology.

>> Now you according to the website I saw started doing this in 2010.

>> 2010, May of 2010 is I’ll call it when we started the business.

[00:02:48]

We made our first sale, we filed our paperwork with the county, and became a legitimate business.

>> But now you according to some of these articles were involved in gardening from a very early age.

>> All my life, yeah, as long as I can remember having a backyard we always had a garden, always.

[00:03:06]

>> So how did you take that hobby if you will, and turn it into a business, what prompted that?

>> Like I said, it was a tough time, with my husband working in construction I was part-time realtor to make ends meet, back in 2010, this was a difficult time to be in both of those careers.

[00:03:25]

And we thought, what can we do with this crummy old, beautiful sun room? But turn it into a greenhouse, and how can we possibly make any money in here? And that’s where we started digging around and found microgreens as a profitable crop that you can grow in a small space.

[00:03:43]

We’re only talking about a hundred square feet, t’s a very small little sun room. But we managed to bring on about ten chefs that we serviced out of that little sun room. Ten restaurants and we would do weekly deliveries. It seemed like every door we’d knock on and introduce our products to them, they’d very quickly sign on and get on the program.

[00:04:07]

And again, 2010, this is sort of a beginning for microgreens, particularly in this region. Everything starts in the West coast and moves to the East. So in California, they had been doing it for years but here in this area, not many people where even aware of what microgreen were.

[00:04:25]

>> I was gonna ask you, somebody doesn’t know what microgreen is?

>> Yeah, so they are vegetable seedlings. We grow about 50 different varieties of vegetable seedlings from seed to harvest is about seven to ten days. So it’s a very quick turnaround. You don’t need a lot of shelf time or growth space required because it’s such a quick turnaround meaning things aren’t sitting growing for more than 30 days or a couple months like traditional crops in the ground.

[00:04:52]

So we would grow them, harvest them, package them, and bring them to a chef. Now the chefs like microgreens because they’re beautiful. They add a lot of flavor to a plate, texture, something interesting or unique that they can bring instead of a sprig of parsley on a plate.

[00:05:10]

Now on the consumer side, there’s a humongous health benefit to microgreens that a lot of people aren’t aware of. They’re super tiny, little sprigs of broccoli are packed with 40 times the nutrition of traditional broccoli. It’s the same seed, same plant but it’s tiny so all the nutrients are concentrated.

[00:05:32]

So I was given the reference of once ounce which is about the size of the palm of my hand is the equivalent to three cups of broccoli. Yeah so.

>> [INAUDIBLE] A little handful of microgreens.

>> A little handful of microgreens is the same as three cups of broccoli as far as vital nutrients and macronutrients are concerned.

[00:05:51]

Not fiber or calories, but all of the nutrition associated to three cups of broccoli.

>> Okay my son is gonna kill me if I don’t ask this, because this was the first thing he asked when I was telling him about micro microgreen. The little baby corns that are in Asian food.

[00:06:07]

>> Corn shoots, yes.

>> Okay, that’s a microgreen?

>> No, those are baby corns. That’s an Asian food, [LAUGH]

>> So what’s the difference between a sprout and a micrograin?

>> That is an excellent question. Nobody ever asks that question, I usually have to explain it without people even knowing there’s a difference.

[00:06:24]

Sprouts are grown in water, typically in the dark and if it’s not done correctly, it’s a breeding ground for bacteria. With sprouts you’re eating the root, the plant, the stem, all of it. And they’re also extremely healthy, like microgreens. But you just have to be very careful about the process of sprouting them.

[00:06:48]

Microgreens I grow in soil, in a greenhouse like you see with sunshine and fresh air and we harvest above the soil. So you leave the root behind and you’re just eating the plant on top. They’re a little heartier more of like a lettuce rather than a sprout. And I believe they have more nutrition because we grown in soil and they absorb nutrition from the elements around as well.

[00:07:12]

>> So, you started this in the Solarium. And I think one of the articles that I saw had you building a greenhouse in your backyard.

>> Yes, that’s the one that Hodge’s now owns.

>> That’s the one, okay, they told me they had bought one from you.

>> Yes, yes.

[00:07:25]

>> So you moved out into that. How big was that?

>> 400 square feet and in that greenhouse, we probably came close to about $10,000 a month in sales in that little 400 square foot greenhouse. We had about 20 chefs and restaurants, but we were still limited. We were growing vertically rather than horizontally.

[00:07:50]

So some things didn’t grow as well as others, they didn’t get the full spectrum of light that they needed. We had hot spots and shade spots that we didn’t want. And we were out of space so about a year after that is when we came over here and built this greenhouse.

[00:08:05]

>> So this is about 2012.

>> 2012 for the first half, 2013 for the, 2000, no, 2013 for the first half, 14 for the back half.

>> Okay, so you live in Harrisburg, this is roughly a ten-minute drive from your house, and it’s sort of rural-

>> Six.

[00:08:24]

[LAUGH]

>> Six, okay.

>> Six-minute commute.

>> That’s great!

>> It’s wonderful.

>> And this is sort of rural Concord, I guess.

>> Yep.

>> You’ve got about five acres here?

>> Five acres.

>> And you’ve now got a greenhouse that’s how big?

>> I think it’s 3,600 square feet.

[00:08:39]

>> So you really have gone big in just about nine years?

>> Yeah, I wish I could say that the dollars reflect the square footage still, when we were making such a good profit on a 400-square-foot space. But remember, we were growing vertically, so now the volume is up, but it’s spread out.

[00:08:59]

So everything grows a lot better, but it certainly didn’t quadruple our [LAUGH] revenues.

>> Right, so let’s talk about your growth, because you’re starting off in a solarium, you really haven’t done this before. How did you even learn about greenhouse warming, microgreens.

>> Every day is something new that I didn’t know.

[00:09:21]

Literally, every time I’m over here I find something new, I build something new, we grow something new, it’s always a learning curve. As you saw when you walked up, we’re troubleshooting a boiler system, we’re troubleshooting plumbing, we’re working on electric. We’re constantly working on ways to improve the process or maintain the process.

[00:09:42]

And it’s all trades in industries that we know nothing about.

>> But in 2010, when microgreens really weren’t known in North Carolina, how did you find out about them, how did you get educated in this?

>> It was all trial and error, I’ll tell you the difference between 2010 and now.

[00:09:59]

If you were to search microgreens on YouTube, you are gonna find hundreds of videos on how to and what to do and what not to do. Back in 2010, I think the only videos, if you searched, were videos of interviews like this on YouTube from my farm, not anyone else’s.

[00:10:16]

So it was all trial and error, just get some seed, throw it in some soil, and see what happens.

>> And so I watched you fix your system in here, but how did you learn the operations of a greenhouse and your radiant heat system?

>> I think we start with the basics, each time we implement a new feature to the greenhouse we start with the basics.

[00:10:40]

And then we figure out within a year or so what we like or don’t like about that process. And then we try to recreate something that’ll improve that process. So with our heat system, in particular, we used to use an overhead heater. It just blows hot air over, the air of the greenhouse, and that’s the end of it.

[00:10:59]

It was about $600 a month in propane, and that was just for the first half of the greenhouse.

>> Okay.

>> So when we expanded to the back half of the greenhouse, we thought, well, $1,200 a month is probably what we would be looking at in propane. And that doesn’t sound responsible or sustainable in any way, so how can we improve our heat system?

[00:11:21]

We don’t have the ability for solar efficiently here because of, you can see, how we’re mostly forested. So there are some elements of solar we could do but, at this time, it just didn’t work out. And we thought rain barrels, or not rain barrels, ambient heat barrels, [COUGH] excuse me.

[00:11:45]

And it would take up too much of our valuable workspace inside. So we did some research and found this company in California. Typically, our heat system is typically found on the ground, and you’re growing on the ground. So this was sort of a custom-built, to our specs, to our greenhouse and our crop, heat system.

[00:12:07]

That they designed and shipped it out, piece by piece, and told us who to call to install it. And they laid the whole thing out, and we’ve been working with it ever since, so that was about five years ago. It is a boiler system, it still uses propane, but our heat bill is still that same $600 a month.

[00:12:27]

So we ended up cutting our heat bill in half, basically, yeah.

>> Doubled your size and cut it in half, that’s fantastic.

>> Yes.

>> So 2010, you’re still working on your solarium, do you just start knocking on the doors of restaurants?

>> I did, I had a little wheelie cooler, I had my very first crop of microgreens, which was a broccoli and radish and cabbage and kale mix.

[00:12:48]

Today we call that our lucky mix, and I grew these trays of microgreens, it took me hours to harvest it. To put that into perspective, a tray of microgreens today takes me less than a minute to harvest one tray. And because when you own a business you calculate your hours, and you figure out what your total costs are.

[00:13:10]

So it takes me less than a minute to harvest a tray of microgreens, which is a 10 by 20 flat. And back then, I had four of those trays, and I remember it taking over an hour just to cut it. Just to get it packaged and get it ready for samples and bring it out the door.

[00:13:25]

>> Just cuz you’re better at it now?

>> Yeah, we know what we’re doing, back then it was all new. How do I cut it, should I cut it this tall, should I cut it that tall, is it even ready? Should I let it go a little longer, did I let it go too long, it’s all a learning curve.

[00:13:42]

>> So you just randomly pick restaurants-

>> Yep.

>> And walk in?

>> My first sales call was a customer who, or a restaurant who stood me up in downtown Concord. And I got all dressed up in my business attire, cuz it’s all I know, I’m not a farmer by nature.

[00:13:58]

And got my little wheelie cooler and went downtown and knocked on the door and it said they’re closed. And got on the phone and said, hey, I was supposed to meet you here, and no answer. So here I am with all my samples and thought, all right, well, what about that place?

[00:14:13]

And went next door, knocked on their door, and the owner of the restaurant sat down and made a sandwich. And put the microgreens on top and just started eating it and brought her whole staff out to try it, and they became our first customer.

>> That’s fantastic, who was that, do you mind my asking?

[00:14:26]

>> They were called Brass Button, in downtown Concord, they closed a couple years after that, but it was a cute little sandwich shop.

>> I think I know, they’re right across the street from Gianni’s.

>> Yes, yep.

>> I know exactly where you’re talking about.

>> I can’t remember what’s there now, it’s a cafe, a coffee shop maybe?

[00:14:40]

>> Something like that, yeah, maybe a sandwich shop or something, I can’t remember the name of it either, but wow.

>> Yeah.

>> So you’re now doing 50 varieties of vegetables and greens.

>> Yep.

>> What have you found works really well, what have you found doesn’t work so well in this type of agriculture?

[00:14:57]

>> Spring and fall work really well, [LAUGH] winter and August do not. It’s a struggle, it’s always an adjustment based on the weather. And a lot of folks will grow indoors, in a warehouse even, with artificial light and hydroponics. So you’re feeding your plants with water, which means your nutrition is diluted and so is your flavor and the shelf life.

[00:15:22]

So we prefer to do it this way, but this comes with challenges. We’re always watching the weather, we’re always adjusting for daylight hours, for temperature. If it’s a little colder, it’s gonna take an extra day to grow. If we have a lot of overcast, cloudy a few days, like we’ve had, we have to cut our watering way back, and it’s gonna take a little longer to grow.

[00:15:44]

So it’s constantly an adjustment, those are our challenges here. But I would not trade that because I’m always told that we have the best product in town. And that’s because we grow in the soil with a greenhouse with sunshine.

>> I’m really surprised that the seasonality impacts you that much, I wouldn’t have thought that-

[00:15:58]

>> Absolutely, yeah, mm-hm, we’re heated and cooled, so it’s year-round production. But there’s always, with extreme weather challenges, the snow will pile up On top of the greenhouse, and I will be over here with a broom and a ladder [LAUGH] sweeping it off. You can see this little camera here I’ve got pointed at the greenhouse, that’s so I can monitor what it looks like from the outside when we do have snow and ice piling up and I know when it’s time to come over here and make sure it’s okay.

[00:16:28]

I’ve got a camera on the inside as well that will notify me if something, if a head pops off of my irrigation and something like that, so I could take a look at the inside. It’s all monitored by a computer which has Wi-Fi so I can check temperature and humidity and everything from my phone no matter where I am.

[00:16:46]

These are all measures because we don’t live right here, on the farm. Even though every six minutes I’m always out doing deliveries in Charlotte or, it’s just good to have remote access. But yeah, these are all challenges that we deal with.

>> Well see, your talk about technology was one of my questions, how does technology kinda impact what you do here and how’s it changed since you started?

[00:17:08]

>> I have cameras now, those are new. Not that it’s changed too much because when we came over here we knew immediately that we needed some sort of external remote monitoring system. And that was important since we don’t have a house here. That was important to make sure we can always have eyes on the place.

[00:17:30]

So that was important. We have a back up generator that’s also Wi-Fi and it’ll send me an alert if it kicks on for whatever reason. We have a lot of downed trees and power lines and we’re always dealing with that. So I would say those two are pretty important.

[00:17:49]

We still have a DSL network here. [LAUGH] So I’m running all of this on a DSL. [LAUGH] So, yeah.

>> My God! With regard to the plastic covering here, how durable is that? I mean, if you do have a downed limb, have you had problems with the sheets getting pierced or?

[00:18:12]

>> We’ve had piercings. We haven’t had anything taken down. Knock on some wood for safety. We’ve had a limb fly and just poke right in and just show up and it’s sticking right out. It’s two layers of plastic, I don’t know if you noticed that. So it’s a bubble.

[00:18:35]

The bubble serves as about 12 inches of insulation. It’s just an air chamber, but there is an inflation device on the inside of the greenhouse that fills that bubble and is constantly running. So, if you get a puncture, it just keeps filling and filling and filling and filling.

[00:18:49]

It never stops running. So, I’ve come over and had it look kind of deflated but I’ve never had it down.

>> Are your timer, are your heating system, or they are on timers.

>> Everything’s climate controlled, so thermostats, humid stats, that kind of stuff.

>> Okay, I would have thought there was a thermostat.

[00:19:09]

Okay.

>> Yeah, there’s a couple of soil thermostat to tell us how. So that was the main point of the heat was that we’re heating the soil and not the air. So we have a soil probe that tells us the temperature of the soil. And then, we have an air thermostat for just ambient.

[00:19:26]

>> Now, the types of crops that you do. You said you do about fifty varieties. How have you landed on the types of varieties that you have had selected.

>> I wanna say probably 90% of those have been chef recommendations.

>> Okay.

>> Can you do this, can you do that?

[00:19:42]

Sure, we’ll try it.

>> Okay.

>> Most of those make the cut, as long as it’s something edible and can grow in this environment, then we’ll do it. There’s definitely been a few that I’ve tried, and I can’t think of one right now, that have been just not good ideas or just blegh.

[00:19:59]

So we don’t bother. And when I say we have 50 varieties, our business is primarily a custom grown business. So I’m only gonna be growing the varieties that chefs are asking for. And most of those chefs are standing orders. So they’ll start their seasons in Charlotte and the surrounding area.

[00:20:19]

They’ll start their seasons and say, okay, here’s our spring menu. Can we do this, this, this, this, this? And we start growing those. And we keep them and harvest them every single week and deliver them every single week.

>> Every week?

>> Every week until they come back and say, all right, we’re going into the summer menu.

[00:20:32]

Now we wanna use these. And then we’ll switch their palate to a different whole new menu. So we have the 50 varieties that we know we can grow but they’re not always all growing.

>> Okay, so of those 50 varieties are there some that are more successful than others, less successful?

[00:20:51]

>> Again it depends on the season. Right now my top winners in the greenhouse are cilantro, basil. We’ve got about a ten degree differential without heat in that greenhouse. So we already consider us in a May climate without heat in the greenhouse. So whatever grows really well in early May grows really well right now.

[00:21:14]

And then, today, it’s supposed to be what, 79-ish? 75 degrees? It will probably hit 90 in there. My cooler will kick on. It will drop it down to about 80. So it’s really the perfect climate right now to grow a lot of things. But basil, cilantro the top winners this week.

[00:21:32]

Every couple of weeks we have a crop that is just by far stellar compared to the others and year round though, our favorites for year round is that lucky mix. Broccoli, radish, cabbage, kale blended together tastes great. It’s super nutritious, it has a great shelf life and that is what we sell the most of.

[00:21:51]

>> So you started off with a handful of restaurants. Was restaurants your primary initial distribution network?

>> Yeah, absolutely. We also were at the Harrisburg farmer’s market, the Piedmont farmer’s markets.

>> Yeah.

>> We did that for our first year. I have two small children and Saturdays get booked up pretty quick.

[00:22:13]

And evenings are difficult. Everything was difficult which is how [LAUGH] with children. Now, they’re older but at the time, the markets were just, I got to do it. It was the one thing I did not look forward to every single week but it brought in the most money at that time.

[00:22:28]

So we stuck with the markets for a while and when we got too busy we decided to pull out from the market and have partners sell for us. So, several different farmers already at the market, I’d come bring them to them and they’d sell it for us, and it was great.

[00:22:42]

That work usually was a trade, I’d get eggs and everything else from them and they’d sell the micro-greens for me. So that would work out well, since then though we have evolved to retail. So we do Harris Teeter, Whole Foods, Earth Fair, and that is our marketing. There is very little profit, if any at all, in those retail suppliers, but that’s our marketing.

[00:23:06]

So when we have regular consumers say, you at that market?” And we say, no we aren’t at the market but you can go to Earth Fair, or Harris Teeter, or and it’s excellent, to get our product out there.

>> So are you doing much in the way of direct to consumer now, or are you primarily.

[00:23:21]

>> [CROSSTALK]

>> Only by request, I do have a few customers who are either currently struggling with a medical condition or they’re in a rehabilitation mode from cancer or something like that. And they often spend more than restaurants will spend on micro greens.

>> Just because of the nutrients.

[00:23:42]

>> Yeah, yeah. [COUGH] Excuse me.

>> And I see that you are working with some wholesale distributors now.

>> Yeah, we’ve been with Cisco since we came over here. I’m trying to remember what year that was, but it’s been at least five years now with Cisco, and U.S. Foods and Foster Cabinets.

[00:24:03]

There’s also a newer. More local distributor called Freshlist in Charlotte. And Freshlist is a team of people who collect from all the farms, and then they do all the leg work of delivering to the restaurants for you. So this is great because we have a minimum for delivery and if the chef just needs a little tiny container, they can get it from Freshlist.

[00:24:24]

So will drop it all at Freshlist, and Freshlist take it all around for us, it is great. [CROSSTALK]

>> So you are not necessarily doing the deliveries or at least as much of the deliveries as you-

>> It is about 50% customers, direct to the customer and the other 50 is wholesale.

[00:24:40]

Cysco, US Foods.

>> Now I saw on your website that you offer free overnight delivery to-

>> We do.

>> the Carolinas, Virginia. Is that your primary distribution area right now?

>> We don’t do a lot of shipping at all, which I think is the way I would prefer it.

[00:24:56]

It’s a very perishable product and each day that it spends not getting the best care is one day less you’re gonna be able to enjoy it. So, shipping takes a day off the top right away. And then you hope and pray that it gets there all right and in time and that it gets unpacked and put in the refrigerator right away.

[00:25:16]

And I lose control of the product as soon as I put it in the box and put it on the truck. I don’t like to do a lot of it, but we do. We have a ground radius through UPS that is Georgia, North Carolina, Virginia, Tennessee, parts of Tennessee.

[00:25:32]

And that’ll get you a free box of of microgreens.

>> Okay, and are you primarily distributing in that area or is it broader than that?

>> No, so our direct, you mean our direct deliveries? Between Valentine and Davidson are pretty much the bulk of our deliveries.

>> Okay, and beyond, but beyond that-

[00:25:49]

>> Beyond that is Cysco, US Foods-

>> Are they distributing your product nationally?

>> They’re taking all over. Not nationally but they’ve taken up and down the coast.

>> Okay, now when you are delivering this either directly or through one of these distributors, is it always already harvested or are you shipping anything that are continually-

[00:26:07]

>> Nope, all of our products are harvested. The thing with micrograins is that we grow them in such a little amount of soil, that if you don’t harvest it within a week of growing it, it’s gonna need to be transplanted or something. So there’s sort of a misconception about buying living micrograins versus harvested.

[00:26:26]

You’re gonna get the same shelf life whether they’re harvested or whether you cut them yourself in your restaurant. They’re still within a week need to be used so.

>> And a week is sort of the shelf life?

>> Seven to ten days, mm-hm.

>> Okay, cuz I saw on your website that you guys have actually been able to extend the shelf life on a lot of these.

[00:26:44]

>> Yeah, I think that’s because we’re growing in soil and with sunlight. It hardens them a little bit.

>> So what’s the typical day? I hate to ask this question because I just saw-

>> There is no typical day.

>> But what do you typically do on a day in, day out basis?

[00:26:59]

>> We do have a schedule we try to keep. Thursdays are delivery days which means Wednesday is harvest day. So those two are hard and fast. As far as seeding, and all of the other things that take place to run the business, those sort of float with the schedule of the sun, and the season.

[00:27:16]

Right now we see it on Monday, so I come in, throw on some ear buds, and spend a couple hours filling trays. And then we’re out for deliveries on Thursdays, and Tuesdays too, as well.

>> And you said we, are you the only one here, or are [CROSSTALK]

[00:27:30]

>> My dad is a pretty integral part of what we’re doing on a day to day, he’s out doing deliveries right now actually, so Is he local I guess then? Yeah, he lives in my neighborhood actually.

>> That’a great, okay.

>> So but there’s always hiccups and challenges but he’s primarily the go to.

[00:27:49]

We’ve had other, sorry. That’s him. Do you want to pause that for one second?

>> Sure.

>> I’m actually gonna have to take that because

>> So that was your dad out on deliveries.

>> Yeah, so I just need to be available in case something comes up. Like in case he lost an invoice and doesn’t know how much they owe.

[00:28:05]

And you know.

>> Okay, so Is he the only one who helps you out here?

>> Yeah, we’ve had people come in from time to time to do some cleaning and maintenance and that kind of stuff. And lately it seems like we can’t keep that position filled for more than two to three months.

[00:28:20]

It just requires a whole lot of effort to keep filling it, just to have it turn over in two to three months. So I’ve just been kind of picking up the slack and dad’s been picking it up. And I guess we downsized, I don’t know.

>> [LAUGH]

>> [LAUGH] It’s okay, it’s okay.

[00:28:36]

>> So Mondays your seeding days, Wednesdays are harvesting, Thursdays are deliveries.

>> Yeah, so the distributors get multiple deliveries a week. They’re the only ones on the Tuesday as well. So we have a couple delivery days and a couple of harvest days for the distributors. But Wednesdays and Thursday are hard and fast harvest, deliver.

[00:28:54]

>> Now, with the distributors, are you delivering to them, or are they coming here to pick up, or-

>> We’ll deliver to them.

>> Okay, now, with regard to different varieties of products have been anything that you tried just has not worked in the setting?

>> Edible flowers, we’ve got a lot of requests for edible flowers it works in this setting because we’re so fine tuned for micrograins.

[00:29:22]

Anything that doesn’t require those conditions, and when I talk about conditions I’m thinking about the watering in particular. If it doesn’t require 18 seconds an hour of water which is what we water right now, then it’s not gonna do well. And because we don’t have artificial light, our blooms our flowers are only seasonal flowers.

[00:29:43]

So all through winter will get request for edible flowers and we’re not forcing any blooms with artificial lights. So that’s the challenge. Yeah, I’ve tried to grow tomatoes and things like that. But again, it’s so custom tailored greenhouse for micrograins, that anything outside of the micrograin realm is a challenge unless we adapt a whole section of the greenhouse to accommodated.

[00:30:10]

>> Okay, now you mentioned 18 seconds an hour. Is that really how much water is?

>> Yeah, we can get down to one second an hour if we’d like or up to 90 seconds an hour. But in the summer months it’ll be more. As the Sun bakes the soil and it gets hot in there, we’ll water more often.

[00:30:26]

But in the winter, when we have shorter day, it’s about 18 seconds. Right now we’re actually about 30 seconds, but we’re creeping up. We’ll be putting shade cloth on soon, which will help with the heat.

>> So that’s covering the plastic cap?

>> Yeah, and then it’ll feel like a cave in there for about a week, and then we’ll get used to it, and so will the plants.

[00:30:46]

And it’ll be perfect come May, it’ll be the right amount of light.

>> Now, given that you started this in 2010 and by trial and error done a lot of things are there practices or things that you’ve done that you just don’t do anymore because they’re not as successful, you found more efficient ways to do them?

[00:31:11]

>> Always, yeah. Where do I start? There’s always ways that we change what we’re doing and how we’re doing it. Our compost is one of those challenges. Because we grow in soil, we you need to start with a fresh batch of soil each week. Primarily for food safety reasons, we wanna sterile soil each time we start a new crop of micro-greens.

[00:31:37]

So what we take is the old soil and we dump it out here onto a compost pile. It breaks down quickly and it is great soil, it has only been used a week. So that’s always a challenge, is what to do with it, and where to put it, and how to dispose of it.

[00:31:51]

And we do a lot of with the Cabarrus County school gardens, so garden clubs at Cabarrus County schools. And they’ll come and pick up as much as they want, it’s free, and we’ll bring some to them as well. But there’s always a challenge of It’s piling up, what do we do with it?

[00:32:09]

So that’s something we’re constantly evolving. Right now I’m staring at my compost bin while I’m telling you this. We have three bays, and the third bay you can see is piled up over the top. Bay one and two are pretty empty. So while it’s emptying we’re trying to decide, is this system working for us?

[00:32:27]

And I’m thinking no, because we need to get a tractor down here or something that can load it up. And it can’t make that turn by the greenhouse, so we’re always evolving that [LAUGH]. That’s maybe the third or fourth rendition of our compost. So, yeah, there’s always something, from the soil we use, to the amount we water or the heat we apply.

[00:32:52]

>> Now I notice on your website that you focus very much on non-GMO, organic farming.

>> Absolutely.

>> So how challenging is that for you?

>> It’s not at all, actually. Our seed sources are all 100% non-GMO, so we start with that. We only buy non-GMO seeds, that’s easy.

[00:33:16]

The soil itself is a sterile compost, it is peat moss with vermiculite and all natural ingredients. There’s no fertilizers, there’s no additives. There’s nothing added to it, there’s no pesticides. We’re only growing for a week. So what can you possibly do in a week that would make an impact at all?

[00:33:37]

So as long as we don’t apply anything then we’re by default we’re going organic practices. The only challenge at this point is making the decision on whether we should be a certified organic farm or not. And each year we go through this process of thinking about it and always decide that it’s not as important as we think it might be.

[00:33:58]

So we don’t do the certification. Let me rephrase that, being organic is extremely important. Being certified doesn’t seem to make an impact on our customer base. Our customers know how we grow, and they’re welcome to come over and see and learn about the farm itself. So we haven’t had a reason to be certified, but I don’t think we see any challenges with that.

[00:34:24]

>> Well, and I didn’t think about it, but I guess that quick turnaround as far as your harvest goes really does dictate against it, and that, therefore, really does sort of make [CROSSTALK]

>> Yeah, can’t really,

>> Certification process unnecessary.

>> Yeah, Pretty much.

>> Okay, putting aside that certification, are there any other types of certifications, or inspections, or regulations, or-

[00:34:46]

>> Food safety, yeah, absolutely. To sell to the people we want to sell to, we have to continually do annual audits and inspections with the Department of Ag. And they come out and they run through our food safety plan and our harvest practices and everything from the front door to the back door of the greenhouse on how how we are handling the operation.

[00:35:10]

So, we’ve been certified, that’s called Good Agricultural Practices or GAP. We’ve been GAP certified for, I think, five years now. It’s a voluntary program, but it’s something that we think is pretty important for the reassurance. So that when the health inspector shows up at a restaurant and sees our microgreens, they can also see your GAP certificate showing that we’re doing everything we need to do to make sure we’re giving a safe product to that customer.

[00:35:36]

>> And that’s US Department of Agriculture.

>> That is USDA.

>> Okay, and does that then tie into this Food Safety Modernization Act?

>> Absolutely, that program is continually evolving and changing, cuz each year a new incident will pop up and then they’ll reassess their measures and come up with new rules.

[00:35:56]

But we are FSMA ready because we’re certified. So I actually think it may be be mandatory for most farms. For our size farm, it’s not mandatory, but we’ve been doing it for five years.

>> Yeah, I was wondering if you were of the size that you had to actually-

[00:36:13]

>> No, yeah, there’s a dollar amount as well as the size. The whole thing we’re below, but to sell to Sysco, and to sell to Whole Foods and all these other customers, they need the reassurance, so we get it for them.

>> Right, right, but again with the short growing season that you’ve got, are you likely to even have those challenges?

[00:36:34]

>> There’s never been a reported case of anyone getting ill from microgreens.

>> Knock on wood.

>> Yeah, knock on wood [LAUGH].

>> So this is a, really I’m going to change gears on you here, I really like your setting here, I mean this is really just-

>> Yeah I would love to tell you what’s going on out here.

[00:36:49]

So once we got to the point where our growth was manageable and stable inside the greenhouse and we have enough room to continue to expand without having to build something, we started to look outside, and think what else can we do to bring people to the farm. And how can we use our property.

[00:37:05]

Now that the greenhouse, it’s like a well oiled machine in there. Sometimes I’m dealing with the boiler, but other than that it’s a well oiled machine. And it’s calm in maintaining itself. The business is rolling on and everything’s like clockwork. Out here, we thought what can we do to bring in community, we try to practice permaculture.

[00:37:27]

Are you familiar with permaculture?

>> I’m not familiar with that.

>> So with permaculture what you’re doing is you’re working with the land the way its intended to be worked with. So you’re capturing water that’s already on your property. You’re not employing irrigation and everything else. You’re planting things that are native, things that will thrive in the current environment of the property.

[00:37:46]

And a big part of all of that is, community, getting the community involved in the farming practice, as well. So, it’s hard to bring community into the greenhouse, other than just a greenhouse tour and then that’s the end. So what we did out here was we created a space where we can hold classes.

[00:38:07]

We can have parties, we can do private events, and all with the permaculture practice in mind. So we’ve tried to plant an edible forest out here. We’ve got hops that’ll grow up on that trellis. Hardy kiwis and blueberries and all kinds of things that’ll be constantly bringing interest out to this part.

[00:38:30]

What we’re sitting in right now is our timber frame pavilion with the wood-fired oven. And so that is actually the focal point [LAUGH] of out here. Everybody thinks that the plants are great, but they wanna know about the-

>> [LAUGH]

>> Wood fired oven. So Mark, my husband, his passion is pizza.

[00:38:48]

He’s perfected the dough, he’s sourced it locally. He mills his own flour, we have a yeast starter from Italy that we’ve brought over. It just goes on and on. And so, we’ll have pizza night out here where you come, bring a bottle of wine and your significant other or a friend and everybody makes their own pie.

[00:39:06]

We go in and we harvest micrograins to bring out to the pizza. Whatever is growing out here, seasonally, we’ll put on the pizza, basil, tomatoes, whatever is in season. And it’s just a fun night of everybody kind of, strangers getting together and learning about each other and about our farm, and yeah.

[00:39:24]

>> I saw that, and my son, again, is a pizza hound.

>> You have to bring him out, yeah.

>> This is gonna be great. So is it just pizza that he’s doing here? Is he doing breads as well?

>> Well, we’ve done, he’s done a bread class, we’ve done ****, we’re also addicted to ****.

[00:39:39]

I don’t know if you ever have fermented foods, but **** is a miracle elixir. We have, we did a **** class, we’ve had a mushroom class out here. The pizza class, the dough, the sourdough starter class. So yeah, any kind of class, we’ve done plants for human health class, we’ve had, We’ve had a wedding out here.

[00:40:05]

We’ve done a lot of interesting Things out here.

>> That’s great, so you pointed me to the hops over here-

>> Yeah.

>> I also saw on your Facebook page, I guess it was called twisted luck hops?

>> That’s still on there?

>> It’s still on there, yeah.

[00:40:18]

Is that not a thing anymore, or?

>> No, it is, we don’t necessarily market it. So I’d say no, it’s not a thing.

>> Now is this associated with the local brewery scene, or-

>> This is a funny story. so Caberas Brewing, you know Caberas Brewing? My husband was working for Criterion Healthcare, which was a medical office building construction company there in Concord.

[00:40:41]

Steve Steinbacker is one of the owners of Criterion. And he also brewing.

>> I didn’t know that was him, okay.

>> Yeah, so Steve said hey, can you guys grow hops at the farm? And we thought well, let’s find out. And all three of us went into classes and we erected this trellis that is 18 feet at the top which is what hops need to grow.

[00:41:02]

They do get from the bottom all the way to the top in one season and then they start growing around and going down the other side. And what we learned at this class though, after our initial investment, is that we need at least an acre of hops to make even one batch of beer.

[00:41:18]

And with that, well, we don’t have that, we’re not gonna be able to do that-

>> Wow.

>> But we loved the idea of incorporating hops here as a trellis. And so this actually works as a great little covered area to sit. This is a backdrop to the wedding that we had.

[00:41:33]

And they do. They fill that whole trellis up with hops from the top to the bottom in one season. And the chefs actually are the ones that buy them, not. But the chefs will buy them and make jams or purées with them, you name it. Ice cream, I’ve had one chef make ice cream with them.

[00:41:50]

>> Wow.

>> Yeah.

>> That’s great. And I see so you’ve got, this is a variety of fruit trees out here?

>> Yeah, most of them are. Look at that Monarch right there.

>> Beautiful.

>> It’s kinda early for a Monarch. Since it just snowed yesterday. [LAUGH]

>> Yeah, I know.

[00:42:03]

>> So we’ve got some plums and some cherries, we’ve got a couple of fig trees. Obviously those aren’t native, but they grow really well, and they’re adapted to this area. We’ve got persimmons, elderberries, I think that’s it. A variety of all. We’ve got blackberries, raspberries, blueberries. Over here we’ve got goji berries and some pomegranates as well.

[00:42:28]

On the trellis is here we’ve got hardy Kiwis. Those are interesting.

>> I was wondering what that was.

>> Yeah, those are a lot of fun. It tastes great.

>> Now, are you just utilizing these yourselves, or are you distributing these as well?

>> No, the hops are really the only thing out here that we will have an abundance of to sell to customers.

[00:42:47]

The rest of it is just for fun.

>> So you mentioned education. It’s on your website. You do some outreach with local schools. You’ve got classes going. Tell me about your educational mission? How did this work come to be?

>> I don’t really know how that evolved. The schools, we got involved with because both of my children are in the school system.

[00:43:10]

I have a fourth grader and a seventh grader. Again when we started though, they’re both in elementary school and we helped our program at the Elementary, we help them get started with their garden club. So from design to supplies, we’re here for whatever they need. And I wanted those programs to evolve because I think it’s probably one of the most important things right up there with balancing a checkbook that kids are not being taught how to grow food.

[00:43:42]

Where food comes from? Doesn’t come from McDonald’s. I don’t even know that that’s real food. So, you probably want to edit that. [LAUGH] We’re not getting sued by McDonald’s. So I think that was part of the passion was to get these programs going. In our several years of working with the schools it is amazing how much they are doing now versus when we started working with these programs.

[00:44:09]

But they have all about farms, I mean not small little gardens anymore. They’ve got like an acre of cultivated property that they’re working with at certain schools with greenhouses and rain barrels. And it’s amazing, and these kids know just as much as I know about growing a garden.

[00:44:26]

It’s wonderful. So I think that’s been sort of a passion is just to keep those programs going, because I think it’s very important. And as far as the adult education again, we’re just trying to find ways to use our property and bring people here, and create something where it creates awareness about what we’re doing.

As well as gives us a way to reach out to people as well. When you work alone or just with your dad, it’s hard to meet new people, so I’m always looking for ideas to get people here, always.

>> You mentioned that there was seasonality aspects to this operation which frankly I had not even contemplated.

[00:45:07]

What are some of the other challenges that someone like me probably wouldn’t think about in running an operation like this?

>> It’s a full-time job. There are a lot of, when we first started, you saw, you obviously did a lot of research before you came here. But you saw that there were a few articles about us.

[00:45:26]

Everyone else saw that there were a few articles about us as well. And those farmers that saw it said well, I can do that, when they’re already running big operations. And this is a full-time job in itself, and it’s just one crop, just micro-variants. So, I think that’s a pretty big misconception, of how much time it takes to actually have it as a business.

[00:45:50]

Now, on a personal level, if you just want to grow some microgreens, it’s a piece of cake. But if you’re trying to grow a business of microgreens, it in itself, there’s a steep learning curve. It’s always evolving, and it is a full-time job, for sure.

>> So have you pursue any type of formal educational training on this?

[00:46:11]

You said it’s a lot of learning. Is there classes you take in or anything like that?

>> Not specific to microgreens, we’ve done a few online courses on greenhouse management, things like that.

>> And there really is not anything formal on microgreens. There has been a few books, I have read lots of books.

[00:46:28]

Anytime there’s a new book I get it just to have it and make sure it’s part of the library. Some of them are great, some of them are my child could write [LAUGH] but it’s good to have them all because you might get one little bit of information you were not aware of.

[00:46:42]

I would like to learn more about soils. pH, things like that soil components, because that’s something I always struggle with in my garden is the soil. So I would love to take more on that, but I haven’t done anything formal. We’ve done some food safety classes, again nothing specific from microgreens, but on the greater agricultural spectrum, there’s a lot out there.

[00:47:12]

>> Now, you said when you started this in 2010, there really was little if anything in the microgreen arena in this area. How has that changed since you’ve been involved?

>> Everyone does microgreens now. [LAUGH] Everyone’s growing microgreens. I just got a call last week from someone in Cornelius who just, according to him spent $250,000 on a property.

[00:47:34]

He has 30,000 square feet of indoor space that he wants to partner with me on. And I thought, No, I’m good. [LAUGH] I’m good but everyone sees this as a big profit center, and again, it’s a full-time job. You’re gonna get out of it what you put in to it.

[00:47:54]

So it’s not a get-rich-quick business. It’s taken us almost ten years to get to the point where we are, and we have a lot of very loyal Customers and a lot of very generous customers as well, who don’t even consider that they’re spending x amount of dollars on microgreens because they see the bigger picture of how they’re working with a farm who’s working directly with them.

[00:48:20]

And they know the farmer, and the farmer knows them and the whole cycle. So I think there’s a lot of relationship building that needs to take place, but as far as the difference between 2010 and now I would say is, I said they’re at least six or seven growers in the Charlotte area that are trying to do it commercially.

[00:48:43]

They kinda go within a year, but some pop up.

>> It’s really not much in the way of longevity.

>> No, I mean, there’s only so many restaurants buying microgreens, and if they’re already buying them from the top producers, then its hard to compete. Its a very competitive market for sure.

[00:49:02]

Its a lot different than every other agricultural market for some reason.

>> So just from agriculture in general, how do you see the Charlotte market as far as the liability of agriculture here not in microfreen but whatever you come in contact with?

>> I see, and I don’t know if maybe I have blinders on because my customers are all amazing, 100% gang-ho on local food scene.

[00:49:27]

I’m sure for every one that I have as a customer, there are some that just don’t care. But I don’t know them, so I can’t speak to that, but we have a pretty strong momentum right now. Are you familiar with the Piedmont Culinary Guild?

>> I saw that referenced in one of the articles, but I had never heard of it.

[00:49:45]

>> Yeah, the Piedmont Culinary Guild is a collaboration of chefs and farmers in the Charlotte, and out to Winston-Salem, and they’re expanding all throughout North Carolina. But primarily start in the Charlotte market, where it’s sort of a warehouse of chefs and farmers where we can work together. A chef will say, I need tomatoes and whose got this kind of pepper?

[00:50:07]

And then the farmers can pipe in with, we have them, I’ll bring them Thursday. So it is a great way to connect the chefs and the farmers. It is also a outreach for education and other. There’s grants available for farmers, there’s marketing opportunities for chefs. There’s always charitable events going on that the Culinary Guild is either hosting or a big part of.

[00:50:33]

So things like that, having programs like that in any region. I can’t imagine or I think it’s a pretty important part of what we’re doing. But it points us in the right direction, it means that we have it and there’s over a hundred members. So we have a momentum is what it means.

[00:50:50]

So, [COUGH] as far as the Charlotte market goes, I think, we have a pretty unique spot.

>> Unique in what way?

>> For restaurants, and farmers, and agricultural industries growing and just the food desserts and the availability of certain things. I think we’re in a unique spot to become the next culinary hoopla, I can’t think of the right word, but Charleston, Greenville, these are all well-known foodie towns.

[00:51:25]

I believe that Charlotte is right there. It’s just a matter of marketing it, like the fact that you don’t know the Piedmont Culinary Guild means we’re not doing the best job of making sure everyone knows about Piedmont Culinary Guild. But having these programs is, I think, key to it all.

[00:51:42]

>> So is this type of farming, I know you’ve got this organization with the Piedmont Culinary Guild, but does a farm like your’s work with the cooperative agencies or anything more traditional farm might work with, or are you a little more specialized in what they can service?

>> Yeah, the only thing about our farm is that not everybody needs microgreens.

[00:52:09]

It’s not a staple or a commodity. It’s not a crop that’ll feed the hungry. It’s a fine dining crop. So we’re sort of limited on places that will that we can help. We volunteer time all the time to do for different programs, but not in the way of crop.

[00:52:36]

Time, yes crop no.

>> Okay, are there aspects of greenhouse farming that insulate use somewhat from the risk that an outside farmer would deal with. You got the same issues with sunlight. You can control your water flow a little bit better, obviously, an outside farmer doesn’t have to pay a heating bill.

[00:53:01]

Are there things that are a differentiator for you?

>> In terms of risk or?

>> In terms of risk, in terms of making sure that your crops are not prone to insects, not prone to any other issues?

>> I think another farmer, once called us fake farming. Another one called us lazy farming.

[00:53:27]

And I will maybe agree with both of those because I’m not on my hands and knees digging trenches, but you did see me get blasted with a hose of rust water from my boiler. So in some aspects, yes, it is easy farming in that it’s not as labor intensive.

[00:53:49]

The most rigorous activity I do on a day-to-day basis is lifting a three cubic foot bag of dirt, and I do that many times a day. But I’m not shoveling, and I don’t have big equipment. My overhead is a lot lower because I don’t have big equipment, I don’t have acres that I’m cultivating, I have inches that I’m cultivating.

[00:54:11]

So we are shielded in other ways though we’re more at risk in the food safety world microgreens are lumped into that sprout category which is a high risk crop. So our insurance premiums are through the roof just to have the amount insurance required to sell to the people we sell to.

[00:54:31]

And yeah, and so it’s kind of a, it’s a balance.

>> It’s a little bit of a wash.

>> Yes.

>> Where your strengths are or your avoiding risk your picking it up elsewhere.

>> Yeah.

>> Okay, what are some of the farmers comments lazy farming.

>> [LAUGH]

[00:54:51]

>> What are some of the misperceptions that folks have about greenhouse farming, or microgreens that you’ve come across?

>> Again, it’s that full time a lot of people think this is just a part time gig. Anyone who’s running any business, agriculture or other, knows that that’s [LAUGH], it’s always a full time gig.

[00:55:10]

There’s always something to do. You might not be standing in the greenhouse doing it, but I am sitting at a table doing an interview, or I’m at home doing bookkeeping, or, or I’m out doing deliveries or trying to do sales. Tuesday was the taste of Carolina food show, so I was four hours at a food show.

[00:55:28]

So it is a full time job, that is the biggest misconception. I would say that is probably it.

>> That you you mentioned the gentleman that reached you to try to partner to help him with his operation. What do you see for your future? What do you see for the future of Lucky Leaf?

[00:55:48]

>> It’s funny, when we started we had a white board of our goals and our plans and we only have the two year, the five year, and the ten year plan. And, And we’re approaching ten years.

>> Better get to it. [LAUGH]

>> So I think we need to erase it and start over.

[00:56:05]

Our last few years we have, like I said, let that do it’s thing and shift out here. So our goals are our here to try and build this area of the business, and more outreach, more community type activities. Whereas that brings in the money, this brings in the enjoyment if that makes sense.

[00:56:28]

So bringing that aspect kinda renews the vibe, renews the longevity of the business. It does well, I think. It gives us more avenues to consider other options.

>> And you said you see Charlottesville becoming a Foodie destination like a Charleston.

>> Absolutely, yeah.

>> What other things do you see as far as what your view is in the future for agriculture in this area.

[00:56:53]

>> Well, it’s such a dense area that I feel like it’s hard to see agriculture in the Charlotte area. I mean, here we are in Cabarrus County, we’re not in Charlotte. [COUGH] Excuse me. I consider Charlotte, though, our market. I don’t know. That’s a tough question. I do see a shift in the paradigm of the farmer.

[00:57:19]

The 55 plus aged farmer is now the 30 aged farmer. 44 in my case, I see that shift and with that I’m seeing new energy and new life with all these farms. Not that they weren’t doing it right before but it’s evolving with time, using Podges as a perfect example or Barbie’s.

[00:57:39]

Have you talked to Barbie Farms?

>> Somebody on a project spoke with them.

>> Yeah, so to watch how Barbie’s From their third or fourth generation farm. I have met Tommy Barbie when we first started and he was still running the business at the Farmer’s Market every Saturday, multiple farmer’s markets.

[00:57:57]

Hauling his stuff in, hauling his stuff out. And then as he has sort of taken a step back, Brent Barbie has stepped in, I am watching Brent Kinda shift the way they do things. They don’t. They do maybe one farmers market now. And the rest of it’s restaurants.

[00:58:12]

[SOUND] And wholesale groceries, retail.

>> So is that the trend you’re seeing these young. Younger farmers are not necessarily run of the mom and pop-

>> Right, I feel like they’re doing the paperwork to get them into the retail, they’re doing the paperwork to get them in front of other customers that otherwise wouldn’t even have been on the radar.

[00:58:32]

So when you go into Lowe’s Food and you see all your farmer friends on the shelves at Lowe’s Food or Harriss Teeter, that’s when I’m noticing, and I think that trend will continue.

>> Are you seem more, as younger farmers are coming in, are you seeing more experimentation with methods and crop types and is that shifting [INAUDIBLE]?

[00:58:52]

>> I haven’t noticed too much of that, except that we’re trying to get back to our heirloom roots. Bringing back the Bradford watermelon. Bringing back peanuts. Bringing things that were normally grown here and then kinda sort of stepped away and went to chin or wherever else. Where the watermelons getting pretty much lost to a whole new non-crushable watermelon.

[00:59:16]

Where as the Bradford was a soft squishy but the best tasting. So bringing back some of those heirloom are rice. Our rice industry. I am seeing that being brought back as well. Where we lost seed, now we are resurrecting seed old seed and starting to build up storage of that.

[00:59:33]

I think those things are interesting trends, something to keep an eye on.

>> So our time is about up here and I have jumped around a lot. [LAUGH]

>> I followed you, I hope.

>> No, you have done great. I appreciate it. Is there anything that I didn’t ask or that you think should be reflected in something like this that talks about the history and the growth of foodshed in this area?

[00:59:58]

>> I think what is ultimately going to dictate and drive the direction of any of these industries whether it be restaurants or agriculture or either is the consumer. What I’m noticing is not necessarily farmers changing, but the consumers changing. They’re becoming more aware of what’s happening with our food industry.

[01:00:20]

They’re becoming more aware of why the United States is 50% obese and why illness is rampant and why we’re all on medications and I think people are getting ready to change. To change this, not the farmers. But with that, the farmers have to evolve to accommodate curious consumers.

[01:00:40]

So I’m seeing a lot more on-farm events, farm tours, farm outings, pizza nights at our farm. People want to do that stuff. They are always looking for husband, myself, my kids want. We on the weekends, we love doing that kind of a thing where we can go visit a farm, and you know learn something new about the way someone is growing a crop or whatever it is.

[01:01:03]

But so I’m seeing that trend, and it’s totally consumer driven. That people shifting their farms are in to accommodate visitors and I think that’s great.

>> So is that educational element? You think that’s consumer-driven?

>> Absolutely.

>> Or do you think folks have been hearing from farmers and operations like you need to do some, I mean there’s almost like a chicken and egg, very cyclical.

[01:01:28]

>> It’s probably a balance, but the more I learn, the more I want to learn more. So the more I learn about a particular thing that I’ve always known as just part of the diet. We eat it every day and no big deal. And then you learn something about it and then you start researching.

[01:01:45]

>> The more you dig, you know? But I don’t know, I think it’s consumer, I think the consumers are ready. I think we’re all, I hope we’re all ready. Maybe it’s just my small circle of people I know, but we’re very aware to come over here and talk about sustainable farming.

[01:02:05]

People know what that means now. And they know how to spot it, you know [COUGH] versus big ag or, you know, people are knowing the difference without having to educate so I don’t know which came first but.

>> And how would you tell a consumer to get better acquainted to get better knowledge of about these things.

[01:02:27]

>> Find a farmer, go to a farmer’s market, get to know them. That would be my suggestion.

>> Okay, is there anything else I overlooked?

>> [COUGH] I apologize for my lagging cough, it’s the season.

>> No problem.

>> But no, this was great.

>> Okay, I really appreciate your time.

[01:02:44]

Thank you so much for helping me out here.

>> Yeah, absolutely.

>> We really appreciate your cooperation and your assistance with this. And wish you the very best of luck. This is a fantastic operation-

>> We’ll have to have you out for pizza night, you and you’re son.

[01:02:59]

>> I can see Todd all over this-

>> I’ll let you know.

>> I’m gonna shut this thing down.

>> Do it. Yeah, we usually have